Sand and Cement Screed

Sand and Cement Floor Screed Contractors UK

When it comes to achieving a smooth and level sub-floor, sand and cement screeds remain one of the most reliable and widely used options in the UK.

This screed has been around for decades, continuously proving itself to be a strong and cost-effective solution for home-owners and those in the construction industry.

At GM Floor Screeds, we specialise in installing sand and cement screeds for commercial and domestic projects. This includes small extensions and refurbishments, right up to new builds and large industrial projects.

We are approved installers by main screed manufacturers and suppliers in the UK, meaning our skilled team abides by the highest of industry standards.

Whether you need a strong sub-floor for tiling, vinyl, wood, carpet, or another finish, our expertly installed screeds provide the perfect base for long-lasting flooring.

What Is Sand and Cement Floor Screed?

Sand and cement floor screed, also known as 'traditional screed', has been used in the construction industry for over 50 years. It is a simple yet highly effective mixture which consists of sharp sand, cement, and water. Once laid, this mixture dries into a perfectly level surface, and produces a strong, durable sub-floor.

Unlike concrete, sand and cement screed doesn’t include coarse aggregates like gravel. This gives the sub-floor a smoother finish, making it more ideal for a wide range of flooring types, including tiles, carpet, vinyl, wood, or laminate.

It can also be applied in thinner layers when compared to concrete screed, which is typically thicker and used more for structural support.

Key Types of Sand and Cement Screed

At GM Floor Screeds, we install all major types of traditional screed, depending on your flooring needs:

-

Bonded Screed: This type is applied directly to the concrete substrate using a bonding agent for maximum adhesion and strength. Perfect for thinner applications.

-

Unbonded Screed: This screed is laid over a damp-proof membrane or slip layer to separate it from the base. This improves moisture protection, and boosts the performance of acoustic flooring.

-

Floating Screed: We may use this option if we are installing floor insulation or underfloor heating systems alongside your screeding. This is because it provides a stable and thermally efficient base for flooring where energy-efficiency is a top priority.

Regardless of the specification, we only use materials and application techniques that are approved by main screed manufacturers and suppliers here in the UK. Our team ensures adherence to the highest of industry standards along each stage of the installation, ensuring you are 100% satisfied with the end result.

Advantages of Sand and Cement Screed

Sand and cement screed remains one of the most dependable flooring solutions available today. Its valued by property owners, builders, and architects for its durability and flexibility, and not to mention its cost-affordability. Here's all the key benefits:

- A Cost-effective Solution: Sand and cement screed remains a budget-friendly choice for home-owners and construction workers. As the mixture is relatively cheap to make, at least compared to other screed mixtures, it's a highly cost-effective choice.

- Strong and Durable: It also excels at creating a highly durable sub-floor that can withstand heavy foot traffic and high loads. This makes ideal for both residential and commercial properties.

- Versatile Application: It's also suitable for a wide variety of flooring finishes, making it a highly versatile choice. From tiles and carpets to wood and vinyl, it's ideal for modern renovations and new home builds.

- Suitable for Underfloor Heating: Sand and cement creeds are more thermally conductive than other forms of screeding. This means they pair great with and and cement screeds are commonly used with underfloor heating systems. They encapsulate the space around heating pipes effectively, which allows for even heat distribution and better energy efficiency.

- Customisable for Different Project Needs: Depending on project requirements, reinforcements such as fibres or mesh can be added to enhance crack resistance and overall strength.

- Can Be Laid to Falls for Drainage: For areas requiring drainage, sand and cement screed can also be applied with gradients to direct water flow effectively.

Our Installation Process

At GM Floor Screeds, precision and professionalism defines our work. Our meticulous attention to detail ensures a flawless installation process, with adherence to the highest of industry standards.

-

Consultation & Site Assessment: Our service starts with a consultation where we take the time to understand your unique project requirements. We'll then conduct a thorough site assessment to identify the condition of your existing sub-floor, and any on-site conditions that may determine the specification of the screed required.

-

Preparation & Mixing: With the specifications approved and the project green-lighted, we'll then determine the perfect sand-to-cement ratio for your floor screeding. We'll prepare the screed mixture with premium materials, either on-site or using ready-mix screed for consistent quality.

-

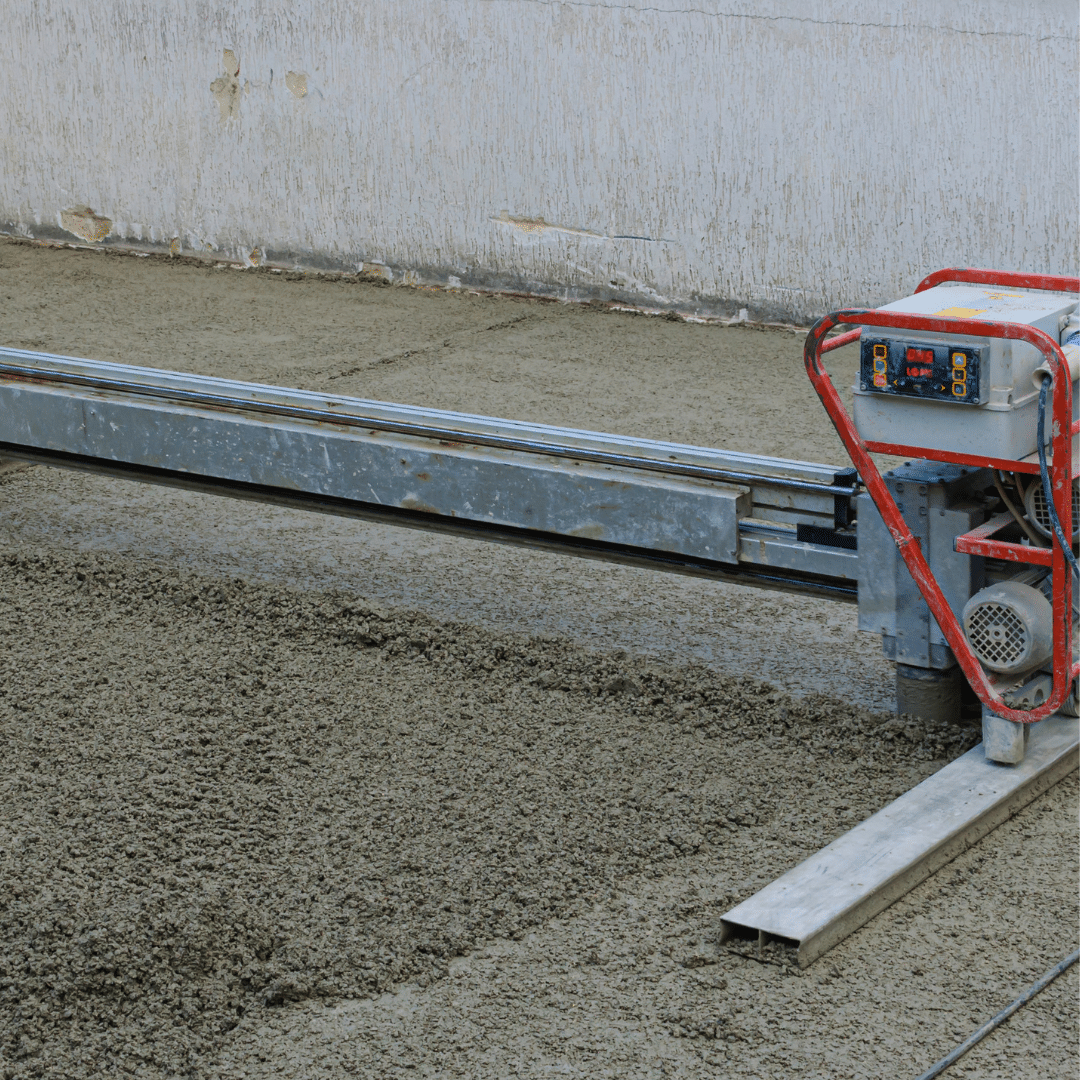

Application: With the screed mix prepared, our skilled technicians will then get to work on installing your screeding on-site with expert attention to detail. We'll use precision tools and the latest floor screeding technology to lay your screed flawlessly, delivering a perfectly level sub-floor.

-

Curing & Drying: We'll provide you with detailed guidance on drying times and moisture testing to ensure your screed reaches full strength before floor coverings are applied.

-

Post-Installation Support: As part of our ongoing commitment to our customers, we provide a high level of aftercare. We'll be on hand to answer your queries and provide professional advice to help you get the most out of your new flooring.

Every installation is carried out by trained screeding professionals, ensuring long-lasting performance and high-quality results.

Considerations For Laying Sand and Cement Screed

-

Drying Time

One key consideration with sand and cement floor screed is the drying process. This type of screed generally dries at a rate of 1mm per day for the first 50mm, and 0.5mm per day beyond that. A 50mm screed will typically take around 50 days to fully dry, though fast-drying additives can be used to accelerate the process.

-

Required Thickness

The minimum recommended thickness varies based on the application:

- Bonded screeds – Minimum 25mm

- Unbonded screeds – Minimum 50mm

- Floating screeds (over insulation) – Minimum 65mm for domestic and 75mm for commercial

-

Moisture Sensitivity

To prevent issues such as cracking or uneven drying, it’s important to ensure the right environmental conditions during the curing process. Proper ventilation and moisture control can significantly improve the final result.

Get a Free Quote Today

So if you're ready to achieve a smooth, durable, and long-lasting sub-floor for your next project, get in touch wtih the experts at GM Floor Screeds today.

We pride ourselves on delivering a reliable and professional service for a range of project briefs, being able to meet a wide range of requirements.

Whether you're working on a home renovation, small extension, commercial new-build, or a large-scale construction project, our experienced team can handle it all.

Get in touch today for a no-obligation quote and let us help you build a strong and stable flooring foundation.

Call us today: 01543 572 177

Email us: info@gmfloorscreeds.com

Serving customers across the UK with expert floor screeding solutions.

FAQs

Typically, it dries at 1mm per day for the first 50mm, and 0.5mm per day beyond that. Fast-drying additives can accelerate the process.

Yes! It works exceptionally well with underfloor heating as it efficiently encapsulates pipes and allows even heat distribution.

Yes, reinforcements such as fibres or mesh can be added for extra durability and crack resistance.

- Bonded screeds are applied directly to the concrete base using a bonding agent, providing maximum adhesion.

- Unbonded screeds are laid over a membrane or insulation, which helps with thermal and acoustic efficiency.

There are two ways in which under floor heating can be installed in a property – whilst the property is being built or it can be fitted after the property has been built. Obviously, the easiest way to install UFH is when a property is being built or renovated.

Any floor type can be laid on top of a under floor heating system, however, there are some types of flooring which work better with the system than others.

Also with some types of flooring, there are certain specifications you must abide by in order for the under floor heating to be as efficient and effective as possible.

Contact Form

Our Address:

GM Floor Screeds Ltd

Unit 9 Brindley Business Park,

Chase Side Drive,

Cannock,

WS11 7GD

Email: info@gmfloorscreeds.com

Landline: 01543 572 177