What Is Liquid Screed? A Complete Guide

If you’re in the process of developing a property or commercial asset, you’ve probably heard of the two most popular forms of floor screeding: liquid screeds and traditional sand and cement screeds. But what is the difference between the two? And which should you use for your project? In this blog, we’ll explain exactly what liquid floor screed is, the key benefits, and which projects benefit most from its use.

What Is Liquid Screed?

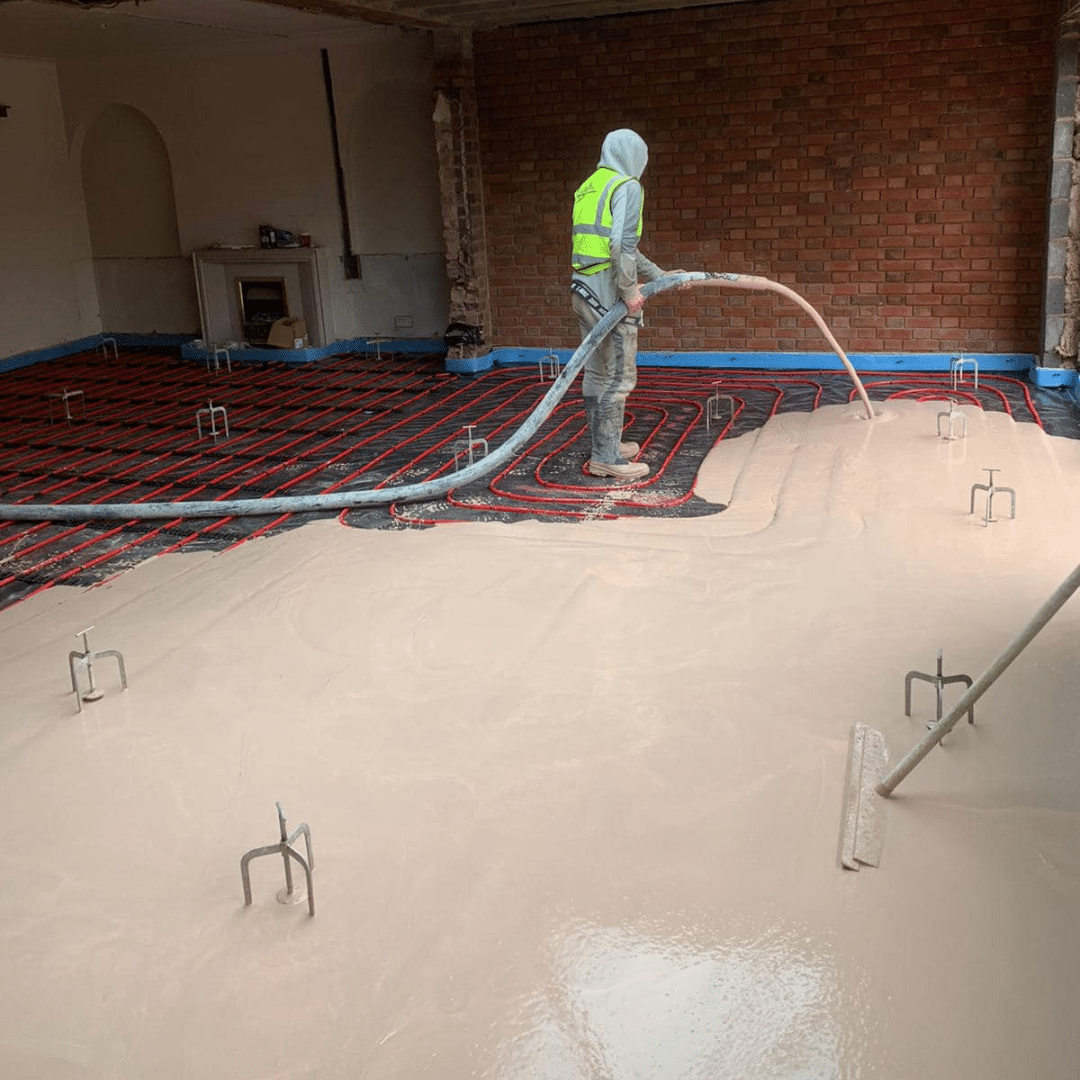

Liquid screed is a liquidous material that is pumped and poured over concrete to create a smooth, level sub-floor. Once pumped, the material quickly dries or “cures” to form a perfectly flat surface for the installation of final flooring, whether that’s wood, carpet, tiles, laminate or another flooring type of your choice.

These screeds can be poured quickly, reducing the need for manual levelling. Their liquidous nature also means they spread evenly across the floor in a self-levelling manner. This is this type of screed can also be referred to as ‘flowing screeds’ or ‘self-levelling screeds’.

As a result of these properties, liquid floor screeds are the new, modern alternative to traditional sand and cement screeds, which take longer to dry and require manual levelling.

Part of their appeal lies in their excellent thermal conductivity, making them the preferred choice for modern residential and commercial buildings which install underfloor heating systems.

From new home builds and extensions, to hospitals, schools, apartment blocks and industrial sites, you will find the application of liquid floor screeds in many of today’s domestic and commercial settings.

Types of Liquid Screeds

There are two main types of liquid screeds:

- Anhydrite (calcium sulphate) Liquid Screed

- Cement-based Liquid Screed

Anhydrite screed, made from calcium sulphate, is the most common used in modern construction. It flows effortlessly across the floor to create an ultra-smooth surface with minimal shrinkage or cracking. It also offers excellent thermal conductivity. Compared to its cementitious counterpart, it boasts slightly higher drying times, and comes with added perks like reduced cracking, whilst it can also be applied in thinner layers which can save on floor height and weight.

Cementitious screed, on the other hand, is based on cement and is more versatile for wetter environments or areas prone to moisture.

While it may dry a bit slower than the anhydrite type, it can offer a stronger and more durable finish. It therefore offers better resistance to water and heavy loads, making it ideal for external applications or rooms which come with moisture concerns.

Liquid Floor Screed vs Traditional Sand & Cement Screeds

For decades, sand and cement screeds have been the traditional choice when it comes to achieving a durable and level sub-floor. Traditional screeds are made by mixing sharp sand with cement and water, usually by hand.

This is to a ratio of 3:1 or 4:1 (sand to cement). These screeds have to be applied to the surface and levelled manually using a float or screeding bar, and the screed itself can take up to a month or more to dry completely.

If applied directly over a concrete base, this is known as bonded screed, and will typically be applied between 25mm-50mm thick. If it is applied over a membrane, such as a plastic sheet, this is known as unbonded screed, where it is normally applied 50mm-75mm thick.

If it is applied over insulation, this is called ‘floating screed’, applied at a minimum of 65mm for lighter loads, and 75mm for heavier loads. To understand how liquid screed has grown to become the preferred choice for modern domestic and commercial floor screeding, it is important to assess what distinct advantages it holds over traditional screeds.

Advantages of Liquid Floor Screeds Over Traditional Screeds

- Reduced Labour Costs: Due to their self-levelling nature, flowing screeds don’t need to be levelled manually using screeding bars or other tools, which saves significantly on labour costs.

- Faster Drying Times: Traditional screeds can take a week or more to dry, whereas liquid floor screeds cure at a much faster rate. They are often walkable within just 24-48 hours, and are suitable for furniture after 1 week.

- Superior Heat Transfer: Because of their more liquidous nature, liquid screeds are more effective at flowing around underfloor heating pipes. This results in better heat transfer and energy-efficiency from your final flooring.

- Eco-friendly alternative: Flowing screed minimises material usage, making them a greener choice when compared to traditional variants

- Low Shrinkage and Cracking: Unlike traditional screeds which are liable to shrinking and cracking over-time, flowing screeds boast low shrinkage and warping. This makes them a more durable solution for many applications.

- Thinner Application: Flowing screeds can be applied in thinner layers when compared to traditional screeds, saving on material cost and reducing curing times. See below for our guide on thickness.

- No Need for Sanding: Traditional screeds need sanding once dry to remove laitance. However, this is not required when installing flowing variants, as these do not produce laitance.

These distinct advantages mean that liquid screeds have all but overtaken traditional screeds as the default choice when it comes to home and commercial construction. They now stand out as the quicker, more modern choice, allowing a wide range of projects to completed quicker, with less labour-input, and with better energy efficiency for underfloor heating.

Disadvantages of Liquid Floor Screeds

However, flowing screeds are not always the perfect solution. There are a few downsides that might make traditional variants more appealing. These include:

- Higher Material Cost: The initial upfront cost of flowing screeds is typically higher than traditional screeds, and so the latter remains a budget-friendly choice for many projects. However, reduced labour hours often offsets this additional expense, which still makes liquid screeds a cost-effective choice.

- Specialist equipment required: Application typically needs pumping machinery and site access for large equipment, which can be a challenge in confined or hard-to-reach areas.

- Not ideal for floors with gradients: Because flowing variants naturally self-level, this can make it tricky to form slopes or drainage gradients for wet rooms and shower floors. Here, manually laying traditional screed may be the better choice.

Liquid Screeds Vs Traditional Screeds: Comparison Table

| Feature | Liquid Screeds | Sand & Cement Screeds |

| Thermal Efficiency | High thermal conductivity for better heat transfer and quicker heating response. | Lower thermal conductivity, resulting in slower and less efficient heat transfer. |

| Thickness | Can be applied in thinner layers, reducing material use and thermal lag. | Requires a thicker application, increasing weight and slowing heating response. |

| Installation Speed | Quick and easy to install using pumpable methods, saving time and labor | Slower installation process requiring manual leveling and increased labour costs. |

| Drying Time | Walkable within 24–48 hours, can handle loads after 7 days. | Takes longer to cure (up to 28 days), delaying project completion. |

| Cracking and Shrinkage | Low risk of cracking and shrinkage. | Prone to cracking and shrinkage. |

| Labor and Cost Efficiency | Lower labor requirements due to faster, pumpable application and reduced material needs. | Higher labor costs due to manual processes and thicker layers. |

What Thickness Should I Lay Liquid Floor Screed?

The thickness to which you will want to apply your liquid floor screed will depend on your chosen application. Here’s our guide on recommended thickness levels:

Bonded Liquid Screeds

Typical thickness: 25–40 mm

Minimum possible thickness: As thin as 12 mm in carefully prepared bonded applications

Standard specification: 25 mm

Unbonded Liquid Screeds

Standard minimum thickness: 30 mm

Allows for thinner applications than traditional sand/cement screeds (which require 50 mm+)

Floating Liquid Screed (Over Insulation)

Domestic applications: Minimum 35 mm

Commercial applications: Minimum 40 mm

Thinner than sand/cement alternatives (65–75 mm)

Liquid Screed Over Underfloor Heating

HTC / High Thermal Conductivity Mix: 20 mm above heating pipes

Standard Screed: 30 mm above heating pipes

How Long Does It Take Liquid Screeds to Dry?

Liquid screeds boast very high drying times, sometimes at a rate 5x faster than traditional screeds. At GM Floor Screeds, our flowing screeds typically cure within 24 hours, and can be walked on from 48 hours onwards.

So if you’re a construction project manager that needs to meet a tight deadline, or you’re a property-owner eager to get your home flooring installed, flowing screeds are a top choice. Whilst the initial cost of the materials may be higher, the time you can save on your project can more than make up for this.

How Do I Lay Liquid Floor Screeds?

Laying liquid screed might look simple, but it’s a far more technical process than most people expect. Firstly, you must ensure the concrete substrate is clean and stable, with perimeter edging installed to allow for expansion. Once the area is sealed, the screed is pumped in using specialist high-pressure equipment that delivers a consistent flow rate.

This is something you can’t achieve with basic DIY tools, and so the right equipment is essential. After pouring, the material then needs to be dappled to release trapped air and ensure a perfectly level surface. Temperature, humidity, and curing conditions all play a major role in how the screed settles, and getting any of these wrong can lead to weak spots, or poor heat transfer over underfloor heating.

Because of these technicalities, most homeowners and contractors hire dependable third party contractors like GM Floor Screeds to handle the installation of flowing screeds. Our installers manage the entire process from preparation to final cure. With our years’ of experience we ensure a smooth, durable finish that performs exactly as it should, without the risks that come with attempting it yourself.

When Should I Use Liquid Screed Instead of Traditional Screed?

Residential New Builds and Extensions:

If you’re a home-owner or property developer, you will want to consider liquid screeds for their ability to provide a perfectly flat and energy efficient sub-floor. Modern homes these days need a perfectly level floor to accommodate a range of floor finishes, including tiles, laminate, carpet, and engineered wood, which is exactly what liquid screeds provide. Almost any type of flooring can be installed above sub-floors installed with flowing screeds, making them a highly versatile and reliable option.

These screeds also allow for greater energy efficiency when using underfloor heating systems. This is because they precisely fill any gaps or voids between heating pipes, meaning less energy is required to heat up your home. These screeds are therefore the ultimate choice for home-woners and property developers, being perfect for everything from new home builds, to modern renovations and extensions.

For Large-Surface Builds

If you need to screed floors with particularly large surface-areas, flowing screeds are the best choice. This is because the material’s self-levelling manner allows it to cover large areas quickly. Flowing screed can cover up to 1,800 m² per day if poured using an accurate pump and pour system (compared to just 125 to 150 m² per day if using traditional screed).

This minimises down-time and saves on labour costs, making it the ideal solution for large open-plan home flooring, apartment block refurbishment, large retail units, warehouses and industrial sites, or sprawling public buildings. This also allows for greater visual consistency, which is crucial for such builds, and guarantees high levels of performance.

For Complex Commercial or Industrial Projects

Liquid screeds are the best option for large commercial or industrial projects, such as the building or renovation of schools, offices, hospitals, showrooms, or large industrial units.

This is because flowing screeds are favoured for their speed of application, high strength, and ability to provide a smooth, perfectly level surface for such complex projects. This allows businesses to minimise project down-time, and obtain a reliable final flooring for high-traffic areas that will last them for years to come.

For Time-Sensitive Projects

If your project needs to meet strict deadlines, then flowing variants are best, as these boast not just the fastest application time, but also the fastest drying time. These screeds are typically walkable within 24-48 hours, and so if you’re a project manager, you can gain peace of mind knowing that follow-on trades or third party contractors can begin work much sooner when compared to traditional screeds, which can take weeks to cure.

For Effective Floor Refurbishment

These screeds are also ideal for renovation projects that are looking to level out uneven or bumpy sub-flooring. By spreading across the floor in a self-levelling manner, all gaps, cracks and other deficiencies are filled and resolved, leaving a perfectly smooth and level surface. As it can be applied in thin layers of just 25-35mm, you also don’t need to worry about additional height being added to your flooring during the refurbishment.

For the Installation of Underfloor Heating Systems

Did you know that liquid screed is now the default choice for underfloor heating systems? This is because the screed’s fluid consistency allows it to fully encapsulate heating pipes. During this process, all air gaps are filled, which leads to excellent thermal conductivity as heat doesn’t get trapped in any voids. This results in even heat distribution across the final flooring and shorter warm-up times. It’s therefore the ideal choice for modern home-owners or property developers who want a warm, cozy environment.

What final moisture levels of liquid screeds are acceptable before installing final flooring?

Before you lay down your final flooring, it’s crucial to check that the screed is dry enough. Typically, the screed should be below 75% relative humidity or 0.5% by weight.

For most finishes like wood, laminate, or carpet, moisture levels should typically be below 1.5–2% for anhydrite screeds and slightly higher for cement-based ones. Resilient floors like vinyl may require even lower levels, so always follow the manufacturer’s guidance. Tiles are a bit more forgiving, but letting the screed fully dry ensures a long-lasting sub-floor.

Testing should be done once underfloor heating has been commissioned and the screed cooled for at least 48 hours. This step is key to avoiding adhesive failure or warping.

What floor coverings are compatible with Liquid Floor Screeds?

Liquid screeds work with almost every popular flooring type, from tiles and natural stone to engineered wood, laminate, vinyl, carpet, and even modern finishes like epoxy resin or microcement. Their self-leveling, smooth surface provides a reliable base, ideal for all manner of commercial and domestic applications. Just make sure to follow manufacturer guidance—some finishes may need extra preparation, like smoothing compounds or profiling, to ensure strong adhesion and long-lasting performance, especially with underfloor heating.

Get In Touch With GM Floor Screeds Today

If you’re in need of high-quality liquid screeds for your next domestic or commercial project, get in touch with the specialists at GM Floor Screeds today. As a national floor screeding company with over 20 years’ experience, we have the expertise to supply your project with a strong, perfectly level sub-floor for your final flooring.

As all-round flooring experts, we can also install underfloor heating, acoustic flooring and insulation alongside our flowing screed solutions. From small home refurbishments to large-scale commercial builds, we handle projects of all sizes, and carry approval from leading UK screed manufacturers. You can count on GM Floor Screeds for a reliable solution to all your flooring needs.